Engineered Solutions

Warehouse Automation

Modern warehouse automation began with the integration of conveyor belt systems. In the time since those innovations, conveyors have played a major role in facilitating the efficient, accurate automation of warehouse operations across applications and industries.

What Is Warehouse Automation?

Types of Warehouse Automation

There are many ways to automate a warehouse, but they can generally be categorized as process automation or physical automation.

- Goods-to-Person (GTP) fulfillment systems

- Automatic Guided Vehicles (AGVs)

- Autonomous Mobile Robots (AMRs)

- Automated sortation systems

- Automated storage and retrieval systems

- Pick-to-light systems

Warehouse of the Future: Trends in Automation

The rapid adoption of automation in warehouses is largely due to a number of persistent trends in the industry. When we consider the future of warehousing, some of the forces driving automation trends include:

- Increasing demand for fulfillment and expedient distribution

- Ongoing labor shortages

- Growth-limiting supply chain issues

Warehouse Technology

- Automated conveyor systems

- Collaborative robots

- Internet of Things (IoT)

- Inventory management systems

- Fleet management systems

- Predictive and proactive maintenance systems

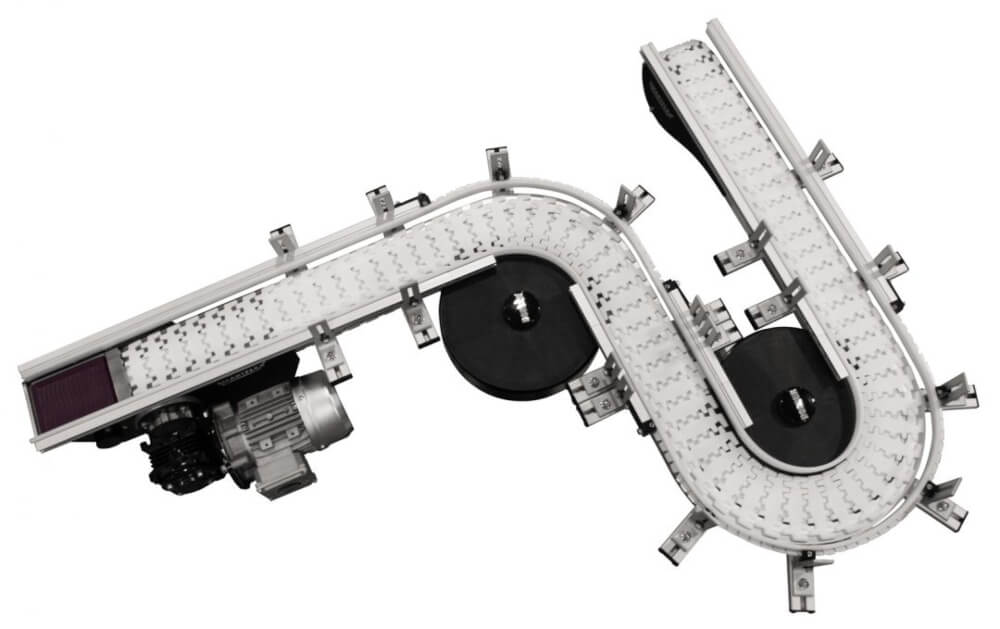

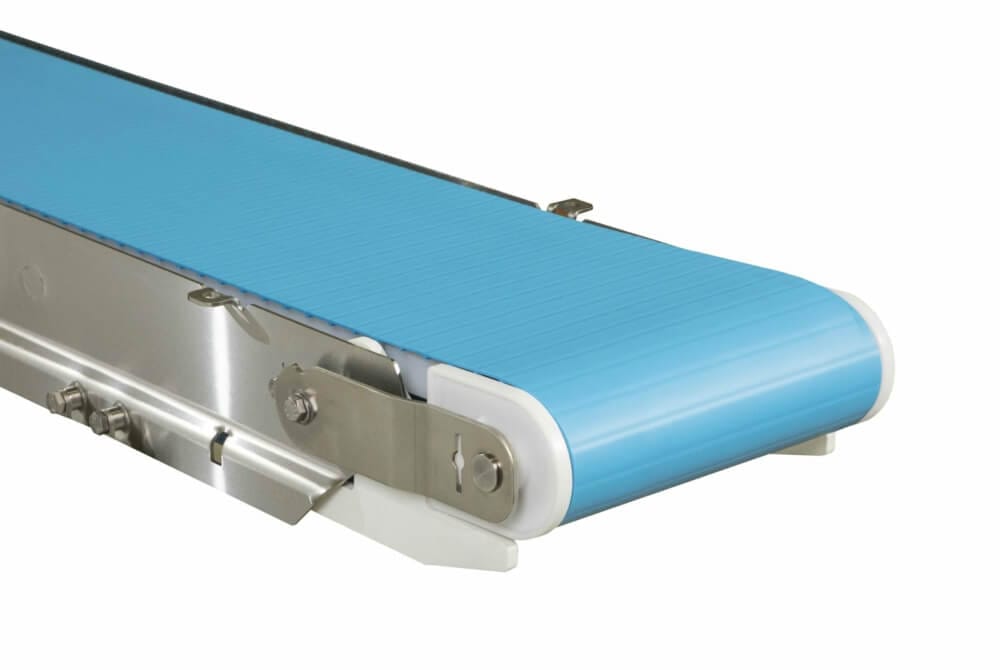

Automated Conveyor Systems

Warehouse Automation Benefits

The many benefits of warehouse automation include the following.

Enhanced Productivity & Efficiency

Improved Worker Safety & Satisfaction

Reduced Error & Inaccuracy

Better Customer Relations

Optimized Use of Space

Conveyor Belt Automation Applications

if you are automating your warehouse, integrating conveyor belt systems will be critical for a majority of applications. The use of a Dorner conveyor will make it easier to automate your processes and facilitate a more efficient and cost-effective warehouse.

Warehousing Management Systems

An effective warehouse management system (WMS) promotes the most efficient and cost-effective operations within a warehouse. Combined with a main line conveyor like our 3200 series or DCMove series, automating processes like accumulation, parts handling, positioning, packaging, and more is a simple task.

Automation of Inventory Management Process

Logistics Automation System

Warehouse Sorting Systems

Automated Warehouse Picking System

Automated Packaging Systems

Automated Warehouse Solutions For Distribution & Fulfillment

Automated Distribution Center

Automated Fulfillment Systems

Frequently Asked Questions About Elevation Conveyors

Looking for conveyor automation solutions? Contact us for a quote today.